One of the least understood subjects by the potential entrepreneurs for the extraction industries is the projection for actual extraction yields and its relation to the leaf quality. This is more important for the vertically integrated units who has their own plantation or have their own contract farming arrangements…..where they can decide about which plant varieties to adopt in their farming.

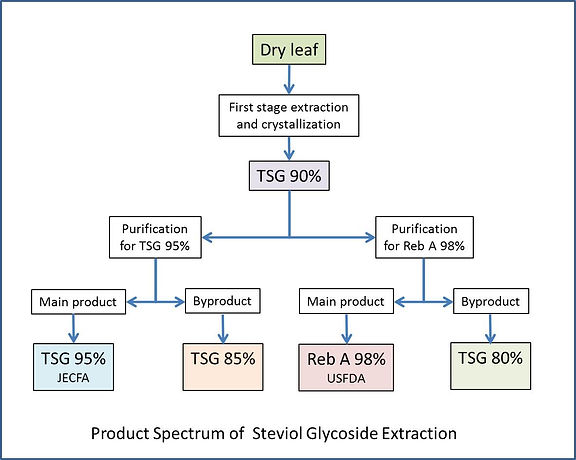

All the extraction process actually yields simultaneously a spectrum of products with different total glycoside content and glycoside profile (i.e. relative percentage of different glycosides). All these products fetch different prices. Thus, to maximize profit, all the production parameters are to be planned in such a way, which maximizes production of products which sale at higher price.

Like almost all other plantation crop based industries, for steviol glycosides, quality and profitability actually originate from the field. For an extraction unit vertically integrated with plantations, the overall economic return depends on the following five variables.

Production Variables for an Extraction Unit

-

Leaf yield per unit area – which depends on the plant variety, plant density in the field and agronomic management of the plants.

-

Total steviol glycoside content of the dried leaves produced in the plantation – This is also a function of plant variety and agronomic management.

-

Percentage of Rebaudioside A in the total glycoside – It is mostly a genetic character for the plants.

-

Extraction efficiency – It indicates how efficient the extraction process is, i.e. what percent of total steviol glycoside present in the leaves can be economically extracted from it.

-

Proportion of in-process material used for TSG 95% (JECFA) and Reb A 98% production.

Now let me address all the variables one by one –

Leaf Yield per unit area

As indicated above, the leaf yield per unit area depends on several factors – mainly variety, plantation density and management.

Desirable varietal traits:

When selecting a variety for the plantation, varieties with the following characteristics are to be preferred.

-

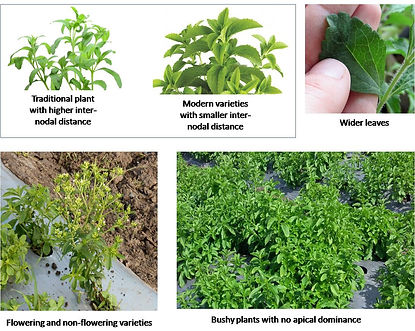

Smaller inter-nodal distance – The plant variety with closely spaced leaf nodes are to be preferred. This is one of the most important phenotypic characteristics for high biomass production potential.

-

No apical dominance – The plants are to be bushy, i.e. should have lots of branches. The apical bud should not be dominant and the plants should not have lanky tall structure.

-

Non-flowering varieties – Flowering in plantations always reduces biomass and glycoside production. Flowering is often triggered by day-length (photoperiod). Plant varieties which are not susceptible to flowering triggering by change in photoperiod are to be selected

-

Wider leaves – Plants with wider leaves often denotes higher biomass production potential.

Plant density:

Very close plant spacing is a characteristic of modern plantations. A population of 150,000 plants in one ha. is not uncommon in well managed plantations. Attaining such high plantation density involves meticulous plantation planning.

Stevia farm with 150,000 plants per ha population density

Total Steviol Glycoside content

This is the prime consideration for selecting any variety for plantation. Nowadays, plant varieties which produce leaves with 18 – 20% total steviol glycoside are also available. But, plantation owners encounter most of the tall promises and appalling underperformance for this feature in varieties procured from sources with questionable credibility. It is always advisable to start plantation with several small trial plots with different varieties, monitor the plant performance in terms of adaptability to local climate, biomass yield and total glycoside content. On the basis of trial result, a particular variety may be selected. Along with the genetic makeup, total steviol glycoside content is also a function of proper nutritional management, irrigation and plant protection.

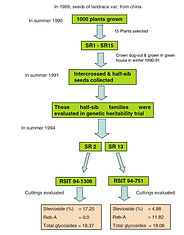

Ref : Sys, E.A., Marsolais, A.A., Brandle, J (1998). Stevia plant named "RSIT 94 - 1306", US Patent PP10562

Breeding Program for development of high TSG Stevia varieties according to Sys et al (1998)

Click on image to enlarge

HPLC of leaf samples from different varieties of stevia having different glycoside profiles

Traditional variety with high Stevioside and low Reb A

High TSG variety with equal amount of Stevioside and Reb A

Typical Morita II variety with high Reb A

Click on thumbnails to enlarge

Percentage of Rebaudioside A in the total glycoside:

This is another very important parameter governing the economic return from a vertically integrated extraction unit. This parameter is almost exclusively dependant on the plant genetics. Rebaudioside A is the glycoside which has the most acceptable taste profile and thus it is the most sought after component in the total glycosides. In original wild varieties, Rebaudioside A was one of the minor glycosides. At present, there are some genetically improved varieties in which the relative percentage of Rebaudioside A may go upto 80%. This parameter almost exclusively controls the proportion of different grades of finished products in an extraction facility.

Extraction Efficiency:

This is a parameter of the extraction technology. Practically, it is not possible to extract the whole quantity of steviol glycoside from the dried leaves. After extraction, a small percentage of residual steviol glycoside always remains with the spent leaves. The percentage of total glycoside, that can be economically extracted from the leaves by a specific technology is termed as extraction efficiency of that technology. Better the technology……higher the extraction efficiency. At present, for most of the commercially adopted technologies, 90% extraction efficiency is a standard feature.

Process Planning:

There are two major commercial product grades for steviol glycosides viz. Total Steviol Glycoside (TSG) 95% as per JECFA specification and Reb A 98% as per USFDA specification. The market for these two products depends on consumer preference in different geographic locations and local regulatory status. Production of these two main products is also associated with co-production of several other product grades, which have also radically different applications and market price. Hence, to maximize the economic return, a well planned product spectrum is an essential prerequisite.

Finished Product

Application/uses

TSG 95%

JECFA Grade. Approved in European Union. Directly salable or as premix. Does not need any reformulation

TSG 85%

Can be sold as only premix for food industries. Reblending with REB A is generally not necessary. May be a good raw material for liquid products.

Reb A 98%

Widespread approval. Directly salable or as premix. A part of the production may be required for reblending

TSG 80%

Can be sold as only premix for food industries. Reblending with REB A is required most of the time

The Planning dashboard:

I have prepared a simple single page excel sheet to study the effect of all variables on the ultimate product mix. A screenshot of the sheet is shown below.

You may access the online excel sheet and play with different variables, to see their effect on the composition of the finished product spectrum

A Scenario Analysis

Let us consider a the variation in parcentage of different finished product with variation in Reb A content of the leaves. For this analysis let us fix the values of the other variables as follows -

Total Steviol glycoside content of the leaves = 15%

Extraction efficiency = 90%

Percentage of intermediate product TSG 90% used for TSG 95% production = 30% and that for Reb A 98% production = 70%

The analysis shows......higher content of Reb A drastically increases the proportion of higer priced Reb A production. Whereas, lower Reb A content results into higher production of the byproduct TSG 80% which has very limited market and fetches lower price.